EDP: 4542129 Part: ER32ODPM6X75 Series: ER*ODP

EDP: 4542129 Part: ER32ODPM6X75 Series: ER*ODP

Available : 0

Product Series Features:

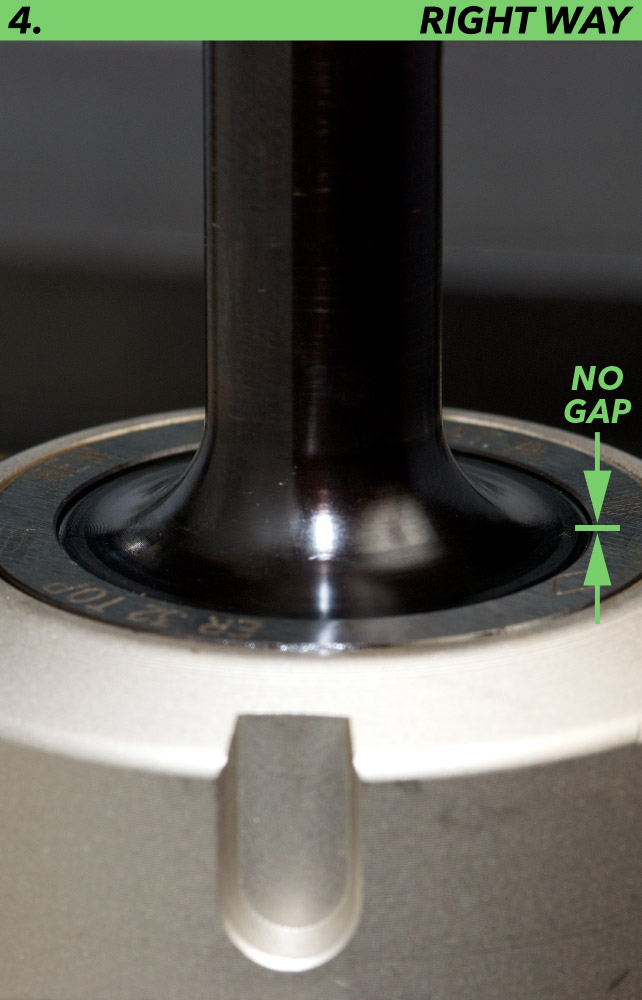

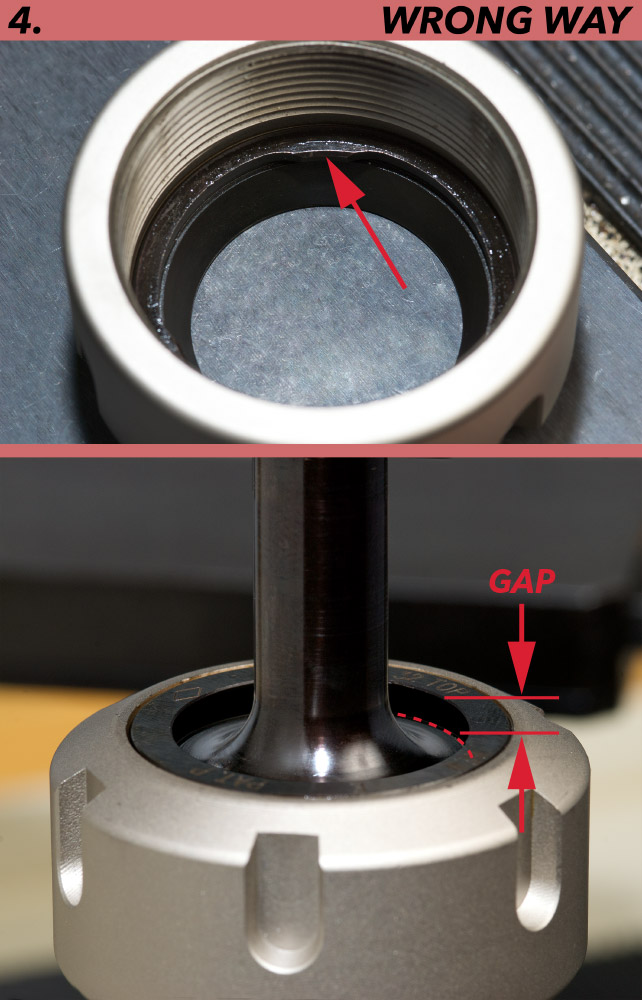

- ER Style Integral Collet

- TopOn Threaded Adaption Adapter

- JET2 Style Ported Coolant

- Max 1450 psi

- For use with standard straight shank tooling