EDP: 3393208 Part: ER32T10SA-02 Series: ER*T - Solid ER, Neck Relief

EDP: 3393208 Part: ER32T10SA-02 Series: ER*T - Solid ER, Neck Relief

Representative image shown ⓘ

The image above is intended to represent the product series for illustrative purposes only. The actual product may vary.

View STEP

Available : 3

International: 15

Product Series Features:

- Solid ER in sizes 11, 16, 20, 25 & 32

- Chip Surfer Connection

- Neck Relief

- Coolant Options

Notes:

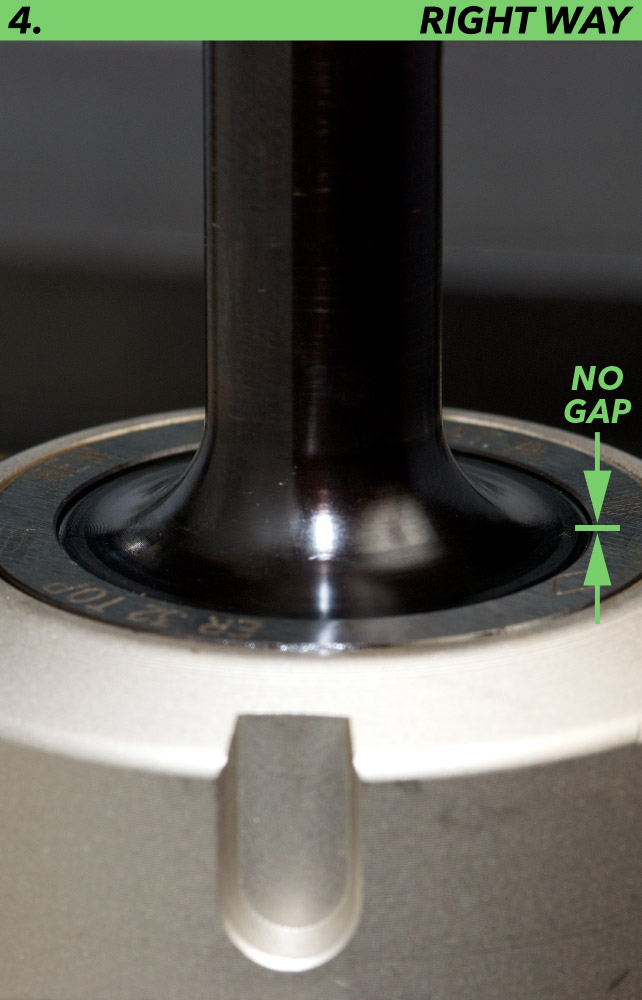

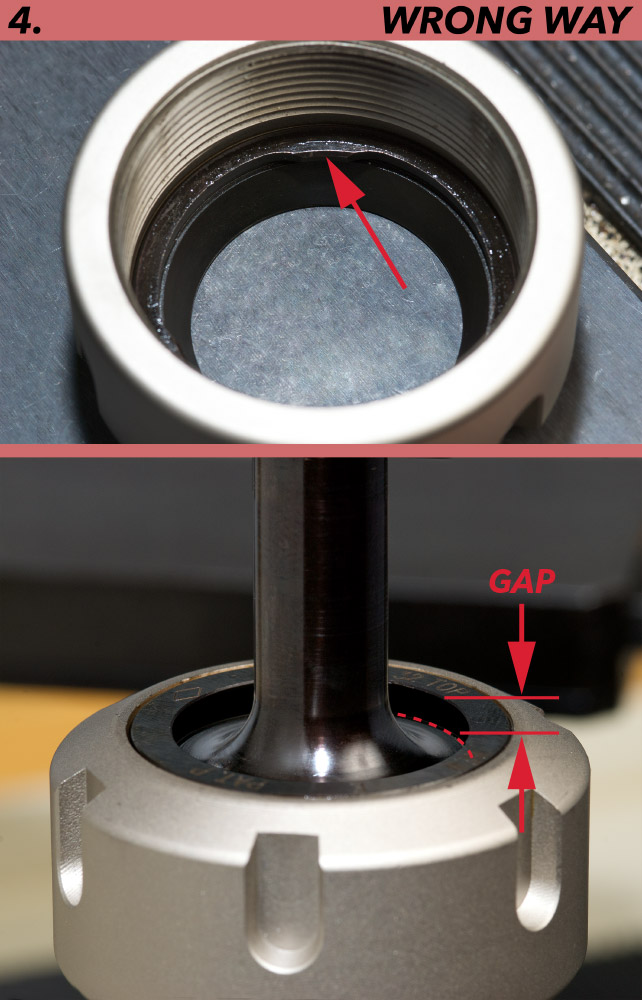

- When assembling, be sure carbide tip is seated firmly on shank with no gap.

- Tightening Torque: T05=60in/lbs - T06=90in/lbs - T08=130in/lbs - T10=250in/lbs - T12=250in/lbs - T15=350in/lbs

- No lubricant on adaption

- Wrenches sold seperately